Ph

+86 15921983298

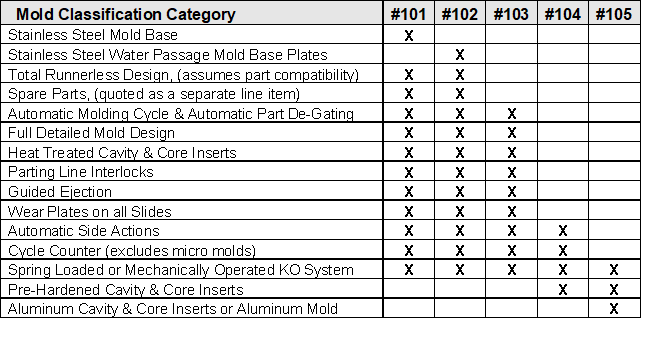

1、Class 101 Molds:

Extremely high volume production injection molds built for lifetime cycles exceeding one million.

2、Class 102 Molds:

Medium to high volume production injection molds built for lifetime cycles not to exceed one million.

3、Class 103 Molds:

Medium volume production injection molds built for lifetime cycles not to exceed 500,000.

4、Class 104 Molds:

Low volume production injection molds built for lifetime cycles not to exceed 100,000.

5、Class 105 Molds:

Prototype only and are molds built for lifetime cycles not to exceed 500.

High Cavitation

The higher the cavities, the more moving parts that must be equally dimensioned, synchronized in their movement, so that they produce parts that are similar to each other.

Low cost focus

Tooling Engineer must be thinking on how to put plastic in the tool, cool it, and eject the part as fast as possible to reduce cycle time. Doing so implies better cooling, robust mechanisms and material management system that all must operated together to reduce cycle time.

High Precision

The tighter tolerances required to archive the higher tolerance and repeatability required by Rain Bird demands a higher quality tool shop along with high quality machinery and tool makers.

High Part complexity

Side action and/or unscrewing features are added to molds to form features. The more side action a mold has, the more mechanisms that must be precisely controlled to form the parts as intended. The mold becomes a transformer-like mechanism.

Small shot size

The smaller shot size means smaller cavities meaning tool makers must have very precise machinery and optical aid devices to manufacture these components. This also requires a higher level of skill from the tool shop.

High volume – Class 101

These molds require higher quality steel with precise management. Features must be made in a highly precision environment and inserted to create a completely interchangeable tool to aid in repair and uptime of the asset. This may result in having hundreds of separate inserts that must be all assembled together to build a mold.

Resin mold-ability

Resin may facilitate (or complicate) higher precision, low shrinkage, less sticking, parts. It may require special steels, complex cooling systems, special auxiliary equipment, and higher mold maintenance

Visual appearance

Certain products must have an expensive, high quality feeling such as car interiors or certain high end electronics